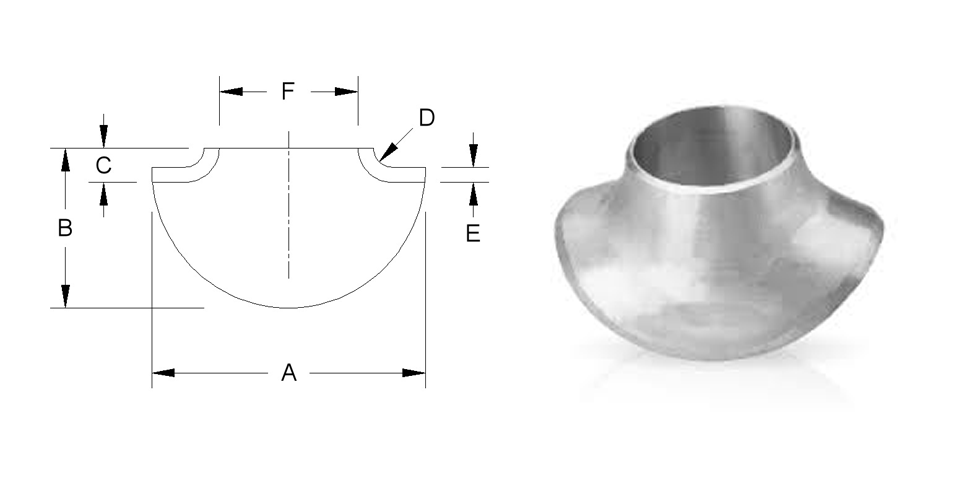

| Pipe Size (NPS) | A | B | Approx. Weight (lb) | |

|---|---|---|---|---|

| STD | XS | |||

| 1/2 | – | – | – | – |

| 3/4 | – | – | – | – |

| 1 | – | – | – | – |

| 1 1/4 | – | – | – | – |

| 1 1/2 | – | – | – | – |

| 2 | 1 7/8 | 1/2 | 1.0 | 1.5 |

| 2 1/2 | 2 3/8 | 5/8 | 2.0 | 2.8 |

| 3 | 2 3/4 | 3/4 | 3.2 | 4.2 |

| 3 1/2 | 3 1/8 | 7/8 | 4.8 | 6.5 |

| 4 | 3 1/2 | 1 | 6.2 | 8.5 |

| 5 | 4 3/8 | 1 1/4 | 10.0 | 14.0 |

| 6 | 5 1/4 | 1 1/2 | 15.0 | 24.0 |

| 8 | 7 | 2 | 31.0 | 48.0 |

| 10 | 8 3/4 | 2 1/2 | 58.0 | 79.0 |

| 12 | 10 1/2 | 3 | 84.0 | 112.0 |

| 14 | 12 1/4 | 3 1/2 | 111.0 | 142.0 |

| 16 | 14 | 4 | 145.0 | 186.0 |

| 18 | 15 3/4 | 4 1/2 | 185.0 | 242.0 |

| 20 | 17 1/2 | 5 | 226.0 | 297.0 |

| 22 | – | – | – | – |

| 24 | 21 | 6 | 333.0 | 428.0 |

- Dimensions per ANSI/ASME B16.9.

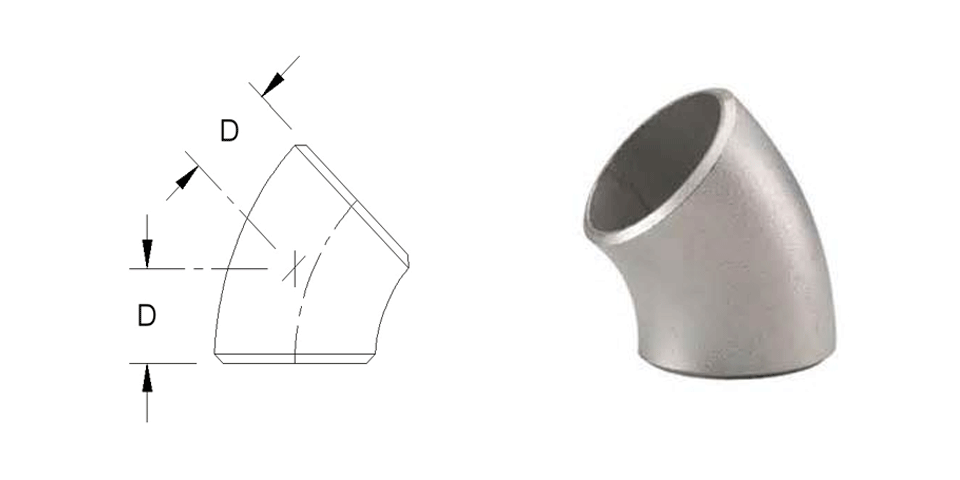

- A 45° elbow long tangent is a long radius (LR) with the centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) and a straight extension at both ends (long tangent) for 2 inch and larger sizes. Tangent elbows provide a straight length at the end to accept a Slip-on Flange. The tangent end for the flange is not beveled.