Showing posts with tag: Long Radius

Jan 18, 2018

Size R J Approx. Weight (lb)

3

6.25

7 3/4

30

4

7

9

45

6

9.5

11 1/2

85

8

14

14

140

10

16.5

16 1/2

255

12

17

19

310

14

19

21 1/2

475

16

21.5

24

630

18

–

26 1/2

840

20

–

29

1080

24

–

34

1640

Flanged long radius bend fittings are not included in AWWA C110/A21.10 For flange dimensions see Flange – ANSI Class 125, C110, DI

AWWA C110/A21.10 – Ductile-Iron and Gray-Iron Fittings (3″ to 48″)

AWWA C104/A21.4 – Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

ASME B16.1 – Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250 (Flange surfaces shall be faced and drilled in accordance with ANSI Class 125)

All ductile iron flanged fittings shall be rated for water pressure of 250 PSI.

Flanged ductile iron fittings in 24 inch and smaller sizes may be rated for 350 psi with the use of special gaskets.

Jan 17, 2018

Pipe Size (NPS) B Approx. Weight (lb) STD XS

2 x 1-1/2

3

1.3

1.8

2 x 1-1/4

3

1.2

1.7

2 x 1

3

1.1

1.5

2-1/2 x 2

3 3/4

2.5

3.3

2-1/2 x 1-1/2

3 3/4

2.2

2.9

2-1/2 x 1-1/4

3 3/4

2.1

2.8

3 x 2-1/2

4 1/2

4.2

5.5

3 x 2

4 1/2

3.5

4.7

3 x 1-1/2

4 1/2

3.2

4.3

3-1/2 x 3

5 1/4

6.0

8.2

3-1/2 x 2-1/2

5 1/4

5.4

7.3

3-1/2 x 2

5 1/4

4.5

6.3

4 x 3-1/2

6

8.2

11.3

4 x 3

6

7.5

10.4

4 x 2-1/2

6

10.5

9.3

4 x 2

6

6.0

8.3

5 x 4

7 1/2

13.1

19.0

5 x 3-1/2

7 1/2

12.2

17.0

5 x 3

7 1/2

11.4

16.0

5 x 2-1/2

7 1/2

10.5

15.0

6 x 5

9

21.0

31.5

6 x 4

9

19.0

27.0

6 x 3-1/2

9

18.0

26.0

6 x 3

9

17.0

24.0

8 x 6

12

39.0

59.0

8 x 5

12

26.0

53.0

8 x 4

12

33.0

48.0

10 x 8

15

71.0

101.0

10 x 6

15

62.0

86.0

10 x 5

15

57.0

78.0

12 x 10

18

112.0

149.0

12 x 8

18

97.0

135.0

12 x 6

18

85.0

116.0

14 x 12

21

137.0

180.0

14 x 10

21

127.0

166.0

14 x 8

21

115.0

151.0

16 x 14

24

177.0

231.0

16 x 12

24

169.0

221.0

16 x 10

24

157.0

205.0

18 x 16

27

238.0

320.0

18 x 14

27

228.0

310.0

18 x 12

27

218.0

300.0

18 x 10

27

208.0

290.0

20 x 18

30

305.0

400.0

20 x 16

30

295.0

385.0

20 x 14

30

280.0

365.0

20 x 12

30

265.0

350.0

20 x 10

30

250.0

325.0

24 x 22

36

428.0

567.0

24 x 20

36

410.0

544.0

24 x 18

36

395.0

523.0

24 x 16

36

376.0

499.0

24 x 14

36

362.0

480.0

24 x 12

36

353.0

466.0

Dimensions per ANSI/ASME B16.9.

A better flow efficiency is achieved using a reducing 90° than using a 90° and a concentric reducer. Also you have one less weld.

Jan 17, 2018

Pipe Size (NPS) A B C Approx. Weight (lb) STD XS

1/2

–

–

–

–

–

3/4

–

–

–

–

–

1

–

–

–

–

–

1 1/4

–

–

–

–

–

1 1/2

–

–

–

–

–

2

3 1/2

1/2

3

1.8

2.5

2 1/2

4 3/8

5/8

3 3/4

3.8

5.0

3

5 1/4

3/4

4 1/2

5.8

8.0

3 1/2

6 1/8

7/8

5 1/4

7.7

11.0

4

7

1

6

11.0

15.0

5

8 3/4

1 1/4

7 1/2

17.0

25.0

6

10 1/2

1 1/2

9

29.0

45.0

8

14

2

12

55.0

85.0

10

17 1/2

2 1/2

15

95.0

130.0

12

21

3

18

146.0

195.0

14

24 1/2

3 1/2

21

185.0

245.0

16

28

4

24

246.0

329.0

18

31 1/2

4 1/2

27

316.0

420.0

20

35

5

30

400.0

475.0

22

38 1/2

5 1/2

33

468.0

625.0

24

42

6

36

571.0

750.0

Dimensions per ANSI/ASME B16.9.

A 90° elbow long tangent is a long radius (LR) with the centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) and a straight extension at both ends (long tangent) for 2 inch and larger sizes. Tangent elbows provide a straight length at the end to accept a Slip-on Flange. The tangent end for the flange is not beveled.

Jan 17, 2018

Pipe Size (NPS) B Approx. Weight (lb) STD XS XXS

1/2

1 1/2

0.2

0.3

–

3/4

1 1/2

0.2

0.3

–

1

1 1/2

0.4

0.5

0.8

1 1/4

1 7/8

0.6

0.9

1.4

1 1/2

2 1/4

0.9

1.2

1.5

2

3

1.6

2.2

3.5

2 1/2

3 3/4

3.3

4.0

7.0

3

4 1/2

5.0

6.5

11.0

3 1/2

5 1/4

6.8

8.4

16.0

4

6

9.0

13.5

20.0

5

7 1/2

15.5

22.0

36.0

6

9

24.5

35.0

65.0

8

12

50.0

71.0

118.0

10

15

88.0

107.0

–

12

18

125.0

160.0

–

14

21

160.0

205.0

–

16

24

206.0

276.0

–

18

27

260.0

340.0

–

20

30

320.0

420.0

–

22

33

394.0

520.0

–

24

36

460.0

600.0

–

Dimensions per ANSI/ASME B16.9.

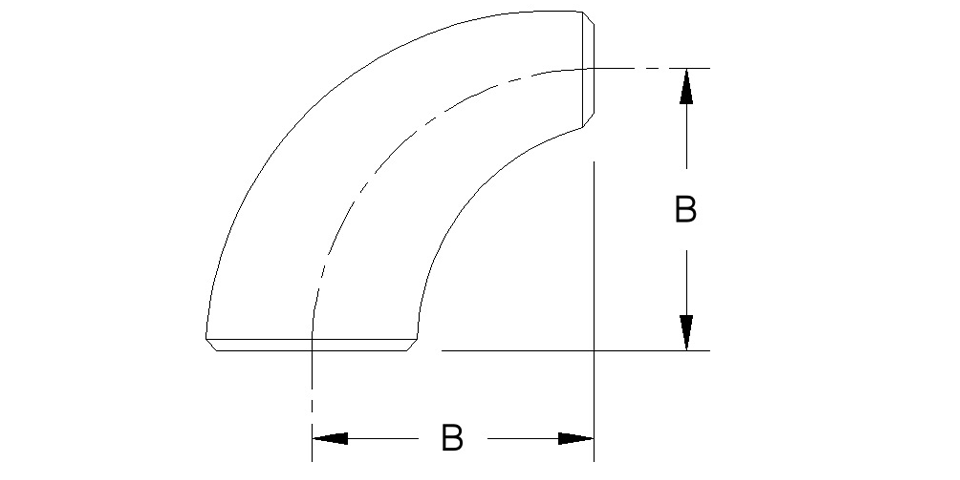

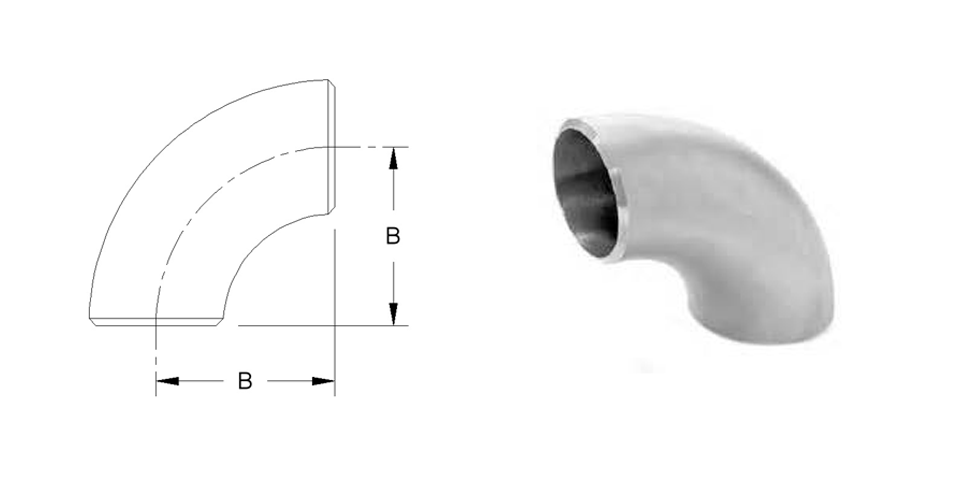

A 90° elbow long radius (LR) has a centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) for 3/4 inch and larger sizes.

Jan 17, 2018

Pipe Size (NPS) J K Approx. Weight (lb) STD XS XXS

1/2

3

1 15/16

0.4

–

–

3/4

2 1/4

1 11/16

0.4

0.7

–

1

3

2 3/16

0.8

1.0

1.5

1 1/4

3 3/4

2 3/4

1.3

1.8

2.7

1 1/2

4 1/2

3 1/4

1.9

2.4

4.0

2

6

4 3/16

3.2

4.4

7.5

2 1/2

7 1/2

5 3/16

6.5

8.0

14.0

3

9

6 1/4

10.3

13.0

22.0

3 1/2

10 1/2

7 1/4

13.0

16.8

32.0

4

12

8 1/4

18.5

25.0

40.0

5

15

10 5/16

30.0

44.0

72.0

6

18

12 5/16

50.0

70.0

130.0

8

24

16 5/16

95.0

142.0

236.0

10

30

20 3/8

117.0

215.0

–

12

36

24 3/8

230.0

320.0

–

14

42

28

325.0

400.0

–

16

48

32

412.0

550.0

–

18

54

36

510.0

690.0

–

20

60

40

640.0

830.0

–

22

66

44

787.0

1040.0

–

24

72

48

890.0

1200.0

–

Dimensions per ANSI/ASME B16.9.

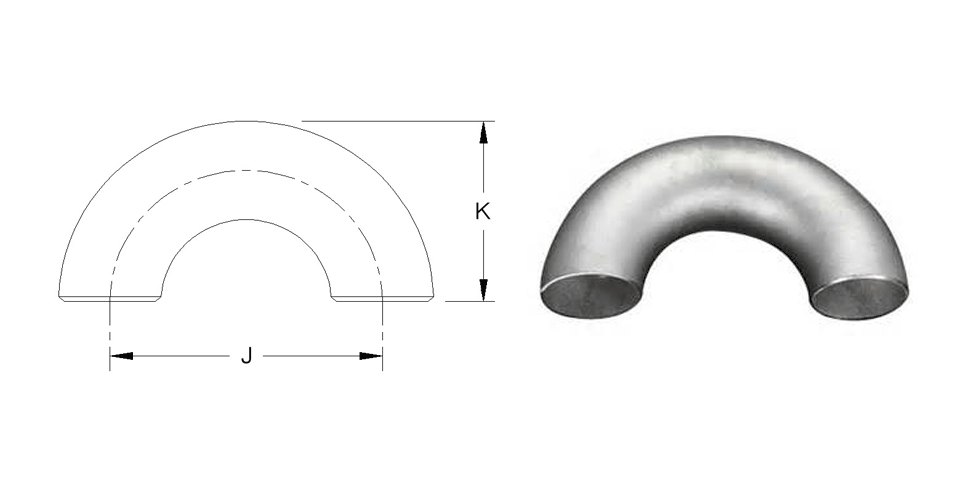

A 180° return long radius (LR) has a centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) for 3/4 inch and larger sizes.

Jan 16, 2018

Pipe Size (NPS) A B Approx. Weight (lb) STD XS

1/2

–

–

–

–

3/4

–

–

–

–

1

–

–

–

–

1 1/4

–

–

–

–

1 1/2

–

–

–

–

2

1 7/8

1/2

1.0

1.5

2 1/2

2 3/8

5/8

2.0

2.8

3

2 3/4

3/4

3.2

4.2

3 1/2

3 1/8

7/8

4.8

6.5

4

3 1/2

1

6.2

8.5

5

4 3/8

1 1/4

10.0

14.0

6

5 1/4

1 1/2

15.0

24.0

8

7

2

31.0

48.0

10

8 3/4

2 1/2

58.0

79.0

12

10 1/2

3

84.0

112.0

14

12 1/4

3 1/2

111.0

142.0

16

14

4

145.0

186.0

18

15 3/4

4 1/2

185.0

242.0

20

17 1/2

5

226.0

297.0

22

–

–

–

–

24

21

6

333.0

428.0

Dimensions per ANSI/ASME B16.9.

A 45° elbow long tangent is a long radius (LR) with the centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) and a straight extension at both ends (long tangent) for 2 inch and larger sizes. Tangent elbows provide a straight length at the end to accept a Slip-on Flange. The tangent end for the flange is not beveled.

Jan 16, 2018

Pipe Size (NPS) D Approx. Weight (lb) STD XS XXS

1/2

5/8

0.1

0.2

–

3/4

3/4

0.1

0.2

–

1

7/8

0.3

0.3

0.4

1 1/4

1

0.4

0.5

0.8

1 1/2

1 1/8

0.4

0.7

1.1

2

1 3/8

0.8

1.2

2.0

2 1/2

1 3/4

1.8

2.1

3.8

3

2

2.6

3.5

5.8

3 1/2

2 1/4

3.5

4.5

8.5

4

2 1/2

4.5

6.1

11

5

3 1/8

7.5

11

19.0

6

3 3/4

12.0

18

32.0

8

5

23.0

35.0

60.0

10

6 1/4

43.0

53.0

–

12

7 1/2

62.0

84.0

–

14

8 3/4

80.0

100.0

–

16

10

100.0

135.0

–

18

11 1/4

126.0

167.0

–

20

12 1/2

160.0

206.0

–

22

13 1/2

197.0

260.0

–

24

15

238.0

300.0

–

Dimensions are listded in inches and millimeters per ANSI/ASME B16.9.

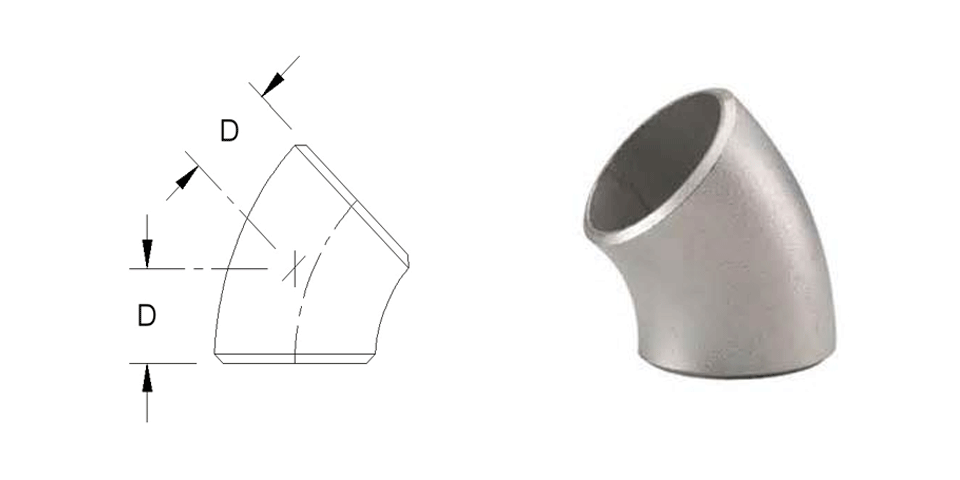

A 45° elbow long radius (LR) has a centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) for 3/4 inch and larger sizes.