Showing posts with tag: Imperial

Jan 17, 2018

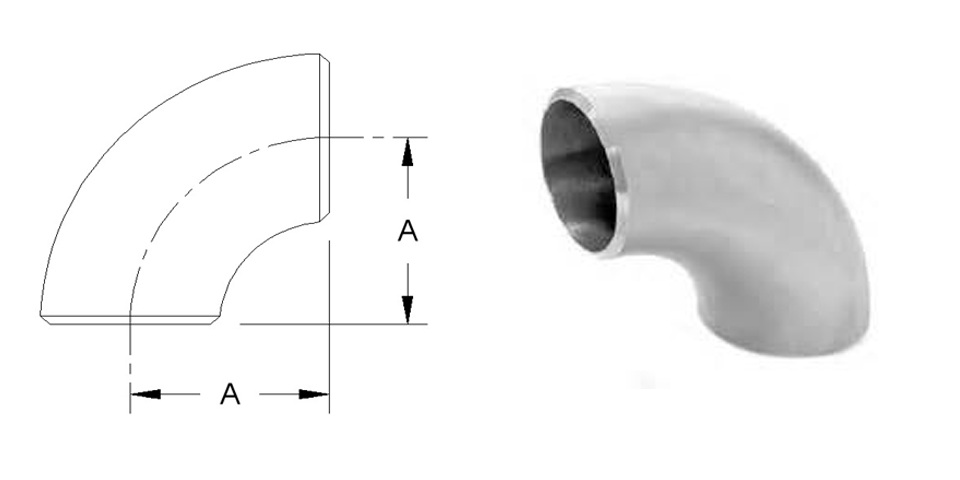

Pipe Size (NPS) A Approx. Weight (lb) STD XS

1/2

–

–

–

3/4

–

–

–

1

1

0.3

0.3

1 1/4

1 1/4

0.4

0.5

1 1/2

1 1/2

0.6

0.8

2

2

1.0

1.5

2 1/2

2 1/2

2.1

2.8

3

3

3.0

4.3

3 1/2

3 1/2

4.5

6.0

4

4

6.3

8.5

5

5

9.6

14.0

6

6

18.0

23.0

8

8

34.0

47.5

10

10

58.0

70.0

12

12

80.0

104.0

14

14

105.0

140.0

16

16

132.0

174.0

18

18

167.0

219.0

20

20

210.0

275.0

22

22

256.0

338.0

24

24

298.0

398.0

A 90° elbow short radius (SR) has a centerline curvature equal to 1 times the nominal pipe size (NPS) for 1 inch and larger size

Dimensions are shown in inches and pounds per ANSI/ASME B16.9.

Jan 17, 2018

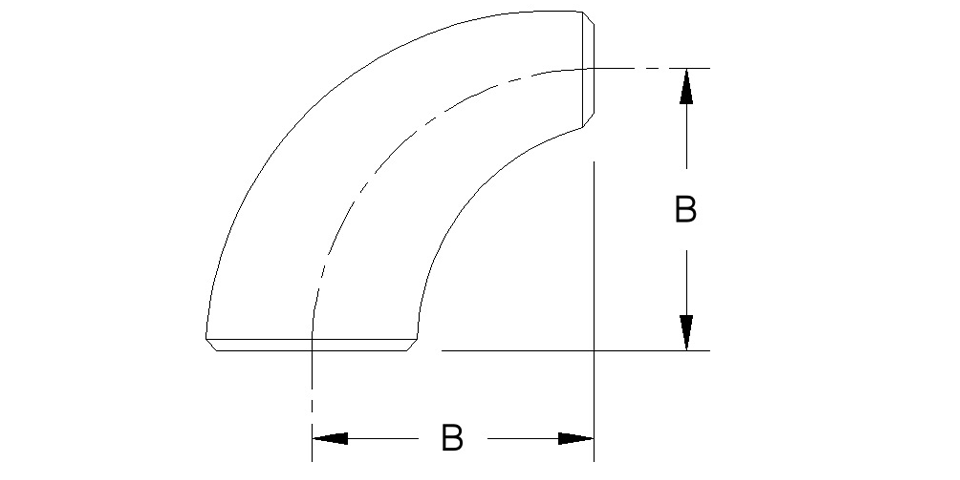

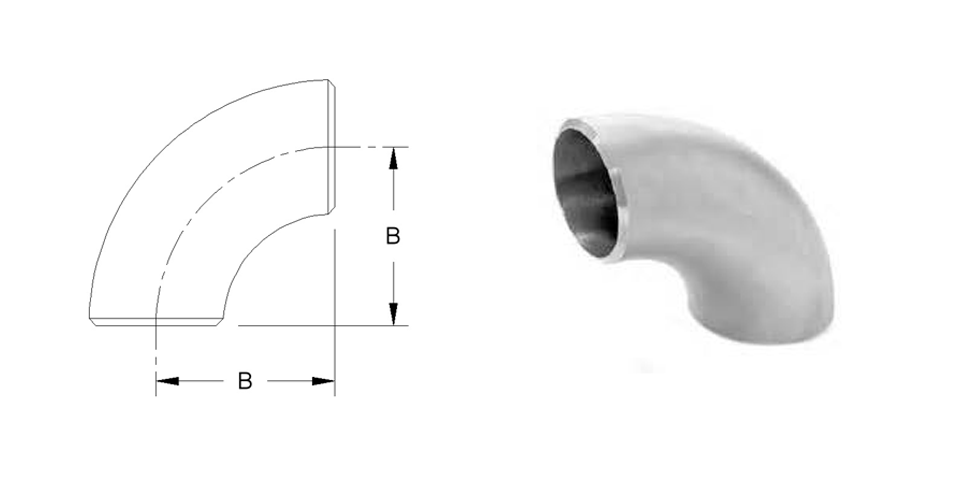

Pipe Size (NPS) B Approx. Weight (lb) STD XS

2 x 1-1/2

3

1.3

1.8

2 x 1-1/4

3

1.2

1.7

2 x 1

3

1.1

1.5

2-1/2 x 2

3 3/4

2.5

3.3

2-1/2 x 1-1/2

3 3/4

2.2

2.9

2-1/2 x 1-1/4

3 3/4

2.1

2.8

3 x 2-1/2

4 1/2

4.2

5.5

3 x 2

4 1/2

3.5

4.7

3 x 1-1/2

4 1/2

3.2

4.3

3-1/2 x 3

5 1/4

6.0

8.2

3-1/2 x 2-1/2

5 1/4

5.4

7.3

3-1/2 x 2

5 1/4

4.5

6.3

4 x 3-1/2

6

8.2

11.3

4 x 3

6

7.5

10.4

4 x 2-1/2

6

10.5

9.3

4 x 2

6

6.0

8.3

5 x 4

7 1/2

13.1

19.0

5 x 3-1/2

7 1/2

12.2

17.0

5 x 3

7 1/2

11.4

16.0

5 x 2-1/2

7 1/2

10.5

15.0

6 x 5

9

21.0

31.5

6 x 4

9

19.0

27.0

6 x 3-1/2

9

18.0

26.0

6 x 3

9

17.0

24.0

8 x 6

12

39.0

59.0

8 x 5

12

26.0

53.0

8 x 4

12

33.0

48.0

10 x 8

15

71.0

101.0

10 x 6

15

62.0

86.0

10 x 5

15

57.0

78.0

12 x 10

18

112.0

149.0

12 x 8

18

97.0

135.0

12 x 6

18

85.0

116.0

14 x 12

21

137.0

180.0

14 x 10

21

127.0

166.0

14 x 8

21

115.0

151.0

16 x 14

24

177.0

231.0

16 x 12

24

169.0

221.0

16 x 10

24

157.0

205.0

18 x 16

27

238.0

320.0

18 x 14

27

228.0

310.0

18 x 12

27

218.0

300.0

18 x 10

27

208.0

290.0

20 x 18

30

305.0

400.0

20 x 16

30

295.0

385.0

20 x 14

30

280.0

365.0

20 x 12

30

265.0

350.0

20 x 10

30

250.0

325.0

24 x 22

36

428.0

567.0

24 x 20

36

410.0

544.0

24 x 18

36

395.0

523.0

24 x 16

36

376.0

499.0

24 x 14

36

362.0

480.0

24 x 12

36

353.0

466.0

Dimensions per ANSI/ASME B16.9.

A better flow efficiency is achieved using a reducing 90° than using a 90° and a concentric reducer. Also you have one less weld.

Jan 17, 2018

Pipe Size (NPS) A B C Approx. Weight (lb) STD XS

1/2

–

–

–

–

–

3/4

–

–

–

–

–

1

–

–

–

–

–

1 1/4

–

–

–

–

–

1 1/2

–

–

–

–

–

2

3 1/2

1/2

3

1.8

2.5

2 1/2

4 3/8

5/8

3 3/4

3.8

5.0

3

5 1/4

3/4

4 1/2

5.8

8.0

3 1/2

6 1/8

7/8

5 1/4

7.7

11.0

4

7

1

6

11.0

15.0

5

8 3/4

1 1/4

7 1/2

17.0

25.0

6

10 1/2

1 1/2

9

29.0

45.0

8

14

2

12

55.0

85.0

10

17 1/2

2 1/2

15

95.0

130.0

12

21

3

18

146.0

195.0

14

24 1/2

3 1/2

21

185.0

245.0

16

28

4

24

246.0

329.0

18

31 1/2

4 1/2

27

316.0

420.0

20

35

5

30

400.0

475.0

22

38 1/2

5 1/2

33

468.0

625.0

24

42

6

36

571.0

750.0

Dimensions per ANSI/ASME B16.9.

A 90° elbow long tangent is a long radius (LR) with the centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) and a straight extension at both ends (long tangent) for 2 inch and larger sizes. Tangent elbows provide a straight length at the end to accept a Slip-on Flange. The tangent end for the flange is not beveled.

Jan 17, 2018

Pipe Size (NPS) B Approx. Weight (lb) STD XS XXS

1/2

1 1/2

0.2

0.3

–

3/4

1 1/2

0.2

0.3

–

1

1 1/2

0.4

0.5

0.8

1 1/4

1 7/8

0.6

0.9

1.4

1 1/2

2 1/4

0.9

1.2

1.5

2

3

1.6

2.2

3.5

2 1/2

3 3/4

3.3

4.0

7.0

3

4 1/2

5.0

6.5

11.0

3 1/2

5 1/4

6.8

8.4

16.0

4

6

9.0

13.5

20.0

5

7 1/2

15.5

22.0

36.0

6

9

24.5

35.0

65.0

8

12

50.0

71.0

118.0

10

15

88.0

107.0

–

12

18

125.0

160.0

–

14

21

160.0

205.0

–

16

24

206.0

276.0

–

18

27

260.0

340.0

–

20

30

320.0

420.0

–

22

33

394.0

520.0

–

24

36

460.0

600.0

–

Dimensions per ANSI/ASME B16.9.

A 90° elbow long radius (LR) has a centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) for 3/4 inch and larger sizes.

Jan 17, 2018

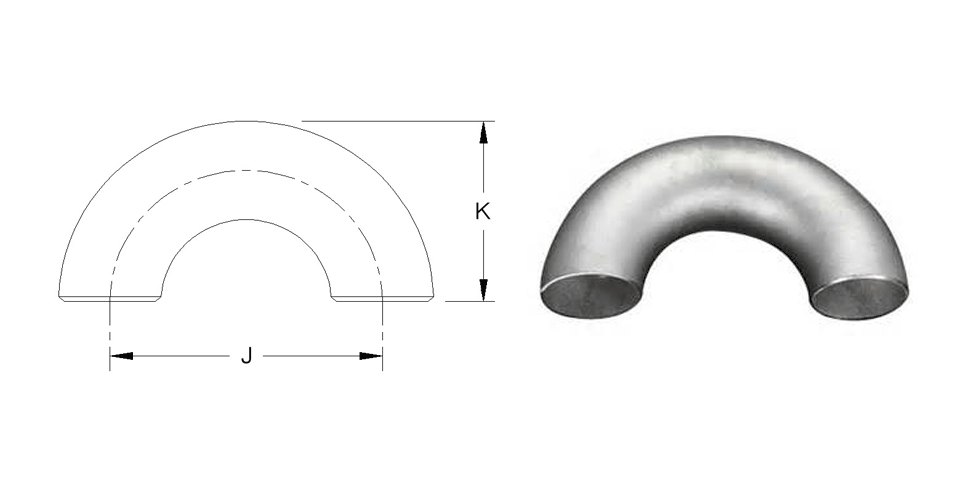

Pipe Size (NPS) J K Approx. Weight (lb) STD XS XXS

1/2

3

1 15/16

0.4

–

–

3/4

2 1/4

1 11/16

0.4

0.7

–

1

3

2 3/16

0.8

1.0

1.5

1 1/4

3 3/4

2 3/4

1.3

1.8

2.7

1 1/2

4 1/2

3 1/4

1.9

2.4

4.0

2

6

4 3/16

3.2

4.4

7.5

2 1/2

7 1/2

5 3/16

6.5

8.0

14.0

3

9

6 1/4

10.3

13.0

22.0

3 1/2

10 1/2

7 1/4

13.0

16.8

32.0

4

12

8 1/4

18.5

25.0

40.0

5

15

10 5/16

30.0

44.0

72.0

6

18

12 5/16

50.0

70.0

130.0

8

24

16 5/16

95.0

142.0

236.0

10

30

20 3/8

117.0

215.0

–

12

36

24 3/8

230.0

320.0

–

14

42

28

325.0

400.0

–

16

48

32

412.0

550.0

–

18

54

36

510.0

690.0

–

20

60

40

640.0

830.0

–

22

66

44

787.0

1040.0

–

24

72

48

890.0

1200.0

–

Dimensions per ANSI/ASME B16.9.

A 180° return long radius (LR) has a centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) for 3/4 inch and larger sizes.

Jan 17, 2018

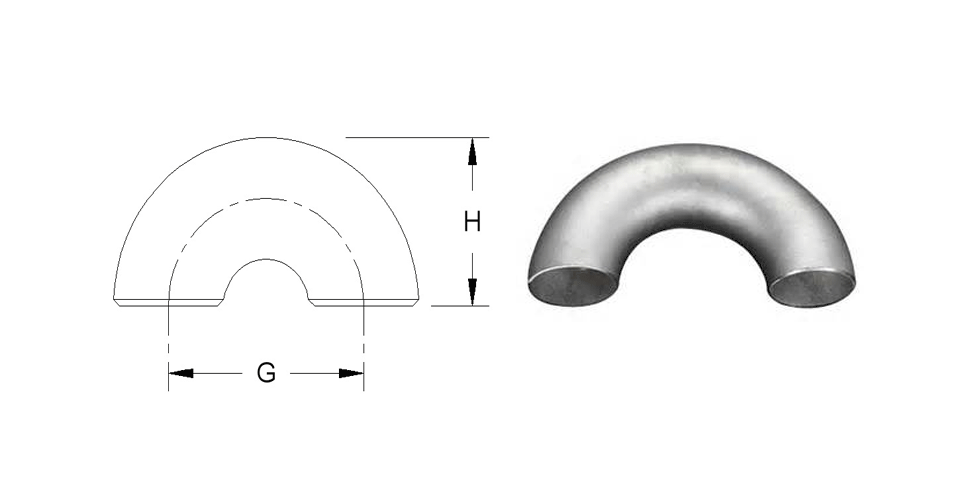

Pipe Size (NPS) G H Approx. Weight (lb) STD XS

1/2

–

–

–

–

3/4

–

–

–

–

1

2

1 5/8

0.5

–

1 1/4

2 1/2

2 1/16

0.8

–

1 1/2

3

2 7/16

1.2

1.5

2

4

3 3/16

2.0

3.0

2 1/2

5

3 15/16

4.3

5.6

3

6

4 3/4

6.0

8.5

3 1/2

7

5 1/2

9.0

12.0

4

8

6 1/4

12.5

17.0

5

10

7 3/4

19.0

28.0

6

12

9 5/16

35.0

46.0

8

16

12 5/16

68.0

100.0

10

20

15 3/8

115.0

140.0

12

24

18 3/8

155.0

218.0

14

28

21

210.0

275.0

16

32

24

260.0

340.0

18

36

27

330.0

430.0

20

40

30

410.0

550.0

22

–

–

–

–

24

48

36

590.0

780.0

Dimensions per ANSI/ASME B16.9.

A 180° return short radius (SR) has a centerline curvature equal to 1 times the nominal pipe size (NPS) for 1 inch and larger sizes.

Jan 17, 2018

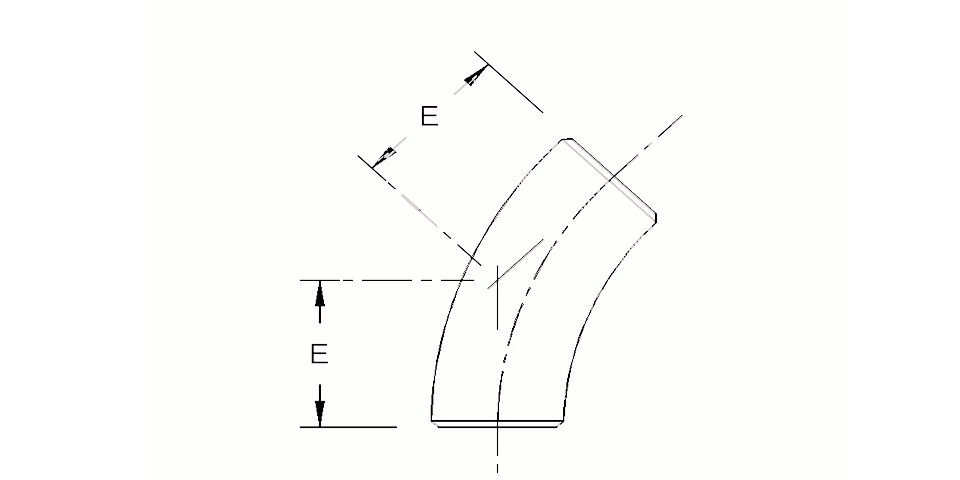

Pipe Size (NPS) E Approx. Weight (lb) STD XS

1/2

–

–

–

3/4

–

–

–

1

–

–

–

1 1/4

–

–

–

1 1/2

–

–

–

2

2 1/2

1.5

2.1

2 1/2

3 1/8

3.0

4.0

3

3 3/4

5.0

7.0

3 1/2

–

–

–

4

5

9.0

13.0

5

–

–

–

6

7 1/2

23.0

35.0

8

10

45.0

70.0

10

12 1/2

80.0

109.0

12

14 7/8

117.0

155.0

14

17 3/8

149.0

200.0

16

19 7/8

195.0

260.0

18

22 3/8

248.0

330.0

20

24 7/8

305.0

405.0

22

27 1/4

368.0

490.0

24

29 3/4

438.0

585.0

Dimensions per ANSI/ASME B16.9.

A 45° elbow three radius is a long radius (LR) with the centerline curvature equal to 3 times the nominal pipe size (NPS).

Jan 16, 2018

Pipe Size (NPS) A B Approx. Weight (lb) STD XS

1/2

–

–

–

–

3/4

–

–

–

–

1

–

–

–

–

1 1/4

–

–

–

–

1 1/2

–

–

–

–

2

1 7/8

1/2

1.0

1.5

2 1/2

2 3/8

5/8

2.0

2.8

3

2 3/4

3/4

3.2

4.2

3 1/2

3 1/8

7/8

4.8

6.5

4

3 1/2

1

6.2

8.5

5

4 3/8

1 1/4

10.0

14.0

6

5 1/4

1 1/2

15.0

24.0

8

7

2

31.0

48.0

10

8 3/4

2 1/2

58.0

79.0

12

10 1/2

3

84.0

112.0

14

12 1/4

3 1/2

111.0

142.0

16

14

4

145.0

186.0

18

15 3/4

4 1/2

185.0

242.0

20

17 1/2

5

226.0

297.0

22

–

–

–

–

24

21

6

333.0

428.0

Dimensions per ANSI/ASME B16.9.

A 45° elbow long tangent is a long radius (LR) with the centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) and a straight extension at both ends (long tangent) for 2 inch and larger sizes. Tangent elbows provide a straight length at the end to accept a Slip-on Flange. The tangent end for the flange is not beveled.

Jan 16, 2018

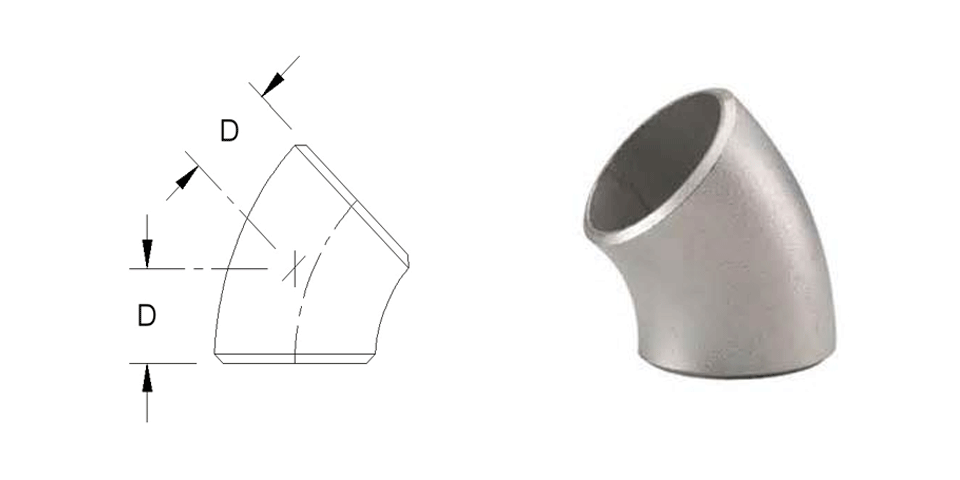

Pipe Size (NPS) D Approx. Weight (lb) STD XS XXS

1/2

5/8

0.1

0.2

–

3/4

3/4

0.1

0.2

–

1

7/8

0.3

0.3

0.4

1 1/4

1

0.4

0.5

0.8

1 1/2

1 1/8

0.4

0.7

1.1

2

1 3/8

0.8

1.2

2.0

2 1/2

1 3/4

1.8

2.1

3.8

3

2

2.6

3.5

5.8

3 1/2

2 1/4

3.5

4.5

8.5

4

2 1/2

4.5

6.1

11

5

3 1/8

7.5

11

19.0

6

3 3/4

12.0

18

32.0

8

5

23.0

35.0

60.0

10

6 1/4

43.0

53.0

–

12

7 1/2

62.0

84.0

–

14

8 3/4

80.0

100.0

–

16

10

100.0

135.0

–

18

11 1/4

126.0

167.0

–

20

12 1/2

160.0

206.0

–

22

13 1/2

197.0

260.0

–

24

15

238.0

300.0

–

Dimensions are listded in inches and millimeters per ANSI/ASME B16.9.

A 45° elbow long radius (LR) has a centerline curvature equal to 1-1/2 times the nominal pipe size (NPS) for 3/4 inch and larger sizes.

Jan 16, 2018

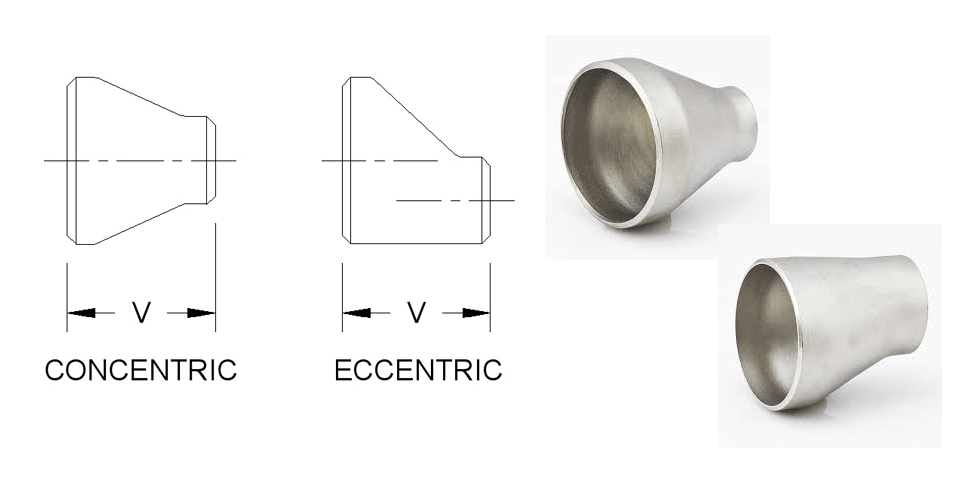

Pipe Size (NPS) V Approx. Weight (lb) STD XS

3/4 x 1/2

1 1/2

0.2

0.3

3/4 x 3/8

1 1/2

0.2

0.3

1 x 3/4

2

0.3

0.4

1 x 1/2

2

0.3

0.4

1 x 3/8

2

0.3

0.4

1 1/4 x 1

2

0.5

0.6

1 1/4 x 3/4

2

0.5

0.5

1 1/4 x 1/2

2

0.5

0.5

1 1/2 x 1 1/4

2 1/2

0.6

0.8

1 1/2 x 1

2 1/2

0.6

0.7

1 1/2 x 3/4

2 1/2

0.5

0.6

1 1/2 x 1/2

2 1/2

0.5

0.6

2 x 1 1/2

3

0.9

1.2

2 x 1 1/4

3

0.9

1.1

2 x 1

3

0.9

1.0

2 x 3/4

3

0.8

1.0

2 1/2 x 2

3 1/2

1.6

2.0

2 1/2 x 1 1/2

3 1/2

1.5

1.8

2 1/2 x 1 1/4

3 1/2

1.4

1.7

2 1/2 x 1

3 1/2

1.3

1.7

3 x 2 1/2

3 1/2

2.1

2.8

3 x 2

3 1/2

2.0

2.6

3 x 1 1/2

3 1/2

1.8

2.1

3 x 1 1/4

3 1/2

1.7

2.2

3 x 1

3 1/2

1.6

2.0

3 1/2 x 3

4

3.0

4.0

3 1/2 x 2 1/2

4

2.9

3.8

3 1/2 x 2

4

2.7

3.5

3 1/2 x 1 1/2

4

2.5

3.1

3 1/2 x 1 1/4

4

2.3

3.2

4 x 3 1/2

4

3.6

4.8

4 x 3

4

3.5

4.7

4 x 2 1/2

4

3.3

4.4

4 x 2

4

3.1

3.9

4 x 1 1/2

4

2.7

3.8

4 x 1 1/4

4

2.6

3.5

4 x 1

4

2.4

3.3

5 x 4

5

5.9

8.3

5 x 3 1/2

5

5.8

8.0

5 x 3

5

5.7

7.8

5 x 2 1/2

5

5.5

7.2

5 x 2

5

5.0

6.6

5 x 1 1/2

5

4.8

6.2

6 x 5

5 1/2

8.6

12.6

6 x 4

5 1/2

8.1

12.0

6 x 3 1/2

5 1/2

8.1

11.6

6 x 3

5 1/2

8.0

11.1

6 x 2 1/2

5 1/2

7.6

9.9

6 x 2

5 1/2

6.9

9.0

8 x 6

6

13.9

20.4

8 x 5

6

13.4

19.5

8 x 4

6

13.1

18.6

8 x 3 1/2

6

12.8

16.1

8 x 3

6

12.4

15.5

10 x 8

7

23.2

31.4

10 x 6

7

22.3

29.8

10 x 5

7

21.8

28.7

10 x 4

7

21.1

25.3

10 x 3

7

20.6

23.2

12 x 10

8

33.4

43.6

12 x 8

8

32.1

37.4

12 x 6

8

31.1

40.6

12 x 5

8

30.5

39.1

12 x 4

8

29.2

38.6

14 x 12

13

63.0

83.0

14 x 10

13

60.0

79.0

14 x 8

13

57.0

76.0

14 x 6

13

55.0

74.0

16 x 14

14

77.0

102.0

16 x 12

14

75.0

99.0

16 x 10

14

72.0

96.0

16 x 8

14

70.0

93.0

16 x 6

14

67.0

91.0

18 x 16

15

94.0

123.0

18 x 14

15

90.0

120.0

18 x 12

15

89.0

118.0

18 x 10

15

86.0

114.0

18 x 8

15

82.0

109.0

20 x 18

20

142.0

186.0

20 x 16

20

138.0

182.0

20 x 14

20

135.0

179.0

20 x 12

20

134.0

176.0

20 x 10

20

132.0

172.0

22 x 20

20

157.0

207.0

22 x 18

20

154.0

202.0

22 x 16

20

151.0

198.0

22 x 14

20

148.0

195.0

22 x 12

20

145.0

182.0

22 x 10

20

141.0

178.0

24 x 20

20

167.0

220.0

24 x 18

20

163.0

215.0

24 x 16

20

160.0

211.0

24 x 14

20

158.0

209.0

24 x 12

20

156.0

206.0

24 x 10

20

153.0

202.0

Dimensions per ANSI/ASME B16.9.

The concentric reducer centerline of the inlet and outlet is at the same level.

The eccentric reducer offset is equals 1/2 times the larger ID minus the smaller ID.