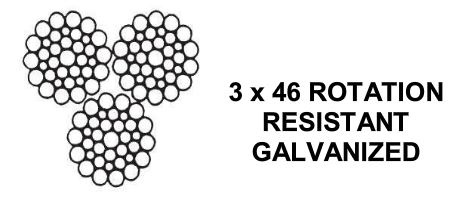

Rotation Resistant Wire Ropes -These wire ropes are specially designed for use when rotation must be kept to a minimum. Strict adherence to breaking-in procedures and proper handling during use are extremely important with these ropes.

The characteristic of these spin resistant wire ropes are that the outer layer is twisted in the opposite direction of their inner layers

19 x 7 Rotation Resistant

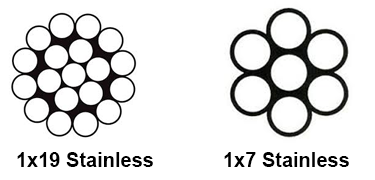

Sized 1/2″ and up meet the performance requirements of API-9A (18×7-WSC). All sizes listed meet the requirements of A.S.T.M. A1023/A 1023M, where applicable. WSC, EIPS * Available in Type 304 Stainless Steel ** Available in Galvanized

| Diameter in Inches |

Approx. Wt. per Ft. in Lbs. |

Breaking Strength in Tons*/** |

| 1/4 * |

0.113 |

2.77 |

| 5/16 * |

0.177 |

4.3 |

| 3/8 * |

0.25 |

6.15 |

| 716″ |

0.35 |

8.33 |

| 1/2 ** |

0.45 |

10.8 |

| 9/16″ |

0.58 |

13.6 |

| 5/8 ** |

0.71 |

16.8 |

| 3/4 ** |

1.02 |

24 |

| 7/8″ |

1.39 |

32.5 |

| 1 |

1.82 |

42.2 |

| 1.1/8 |

2.3 |

53.1 |

| 1.1/4 |

2.85 |

65.1 |

** Breaking Strengths shown are for Bright rope – Stainless Steel 19×7 Rotation Resistant ropes are not covered by the above specifications. Breaking Strengths will vary.

Read Important Warnings and Information

Actual operating load may vary, but should never exceed recommended design factor or 20% of catalog breaking strength.