Synthetic Sling Capacities (lb.)

Basket-rated capacities based on D/d ratio of five times the wire rope’s finished diameter.

Basket-rated capacities based on D/d ratio of five times the wire rope’s finished diameter.

METRIC WIRE ROPES – 6 x 36 wire rope is a more flexible cable wire than 6 x 19 wire rope since it has a higher number of wires per strand. Some of the most common uses are winch lines, choker and boom lines, and works well in marine environments.

6×36 (WS) IWRC, bright, Grade 2160 N/mm2 meets the breaking strength requirements of A.S.T.M. A 1023/A 1023M Wire Rope for General Purposes

* EIPS (Extra Improved Plowed Steel) wire rope has roughly 10% more strength than regular IPS. Independent wire rope core ( IWRC ) provides added strength, reduces the amount of stretch. IWRC wire rope also is resistance to heat and provides extra corrosion resistance over a typical bright wire finish.

| Diameter in mm | Approx. Wt. per Ft. in Lbs. | Breaking Strength in KN* | Breaking Strength in Tons* |

|---|---|---|---|

| 7 | 0.14 | 37.7 | 4.24 |

| 8 | 0.18 | 49.2 | 5.53 |

| 9 | 0.23 | 62.3 | 7 |

| 10 | 0.29 | 76.9 | 8.64 |

| 11 | 0.35 | 93 | 10.45 |

| 12 | 0.41 | 111 | 12.48 |

| 13 | 0.48 | 130 | 14.61 |

| 14 | 0.56 | 151 | 16.97 |

| 15** | 0.64 | 170 | 19.11 |

| 16 | 0.73 | 197 | 22.14 |

| 18 | 0.93 | 249 | 27.99 |

| 20 | 1.15 | 308 | 34.62 |

| 22 | 1.39 | 372 | 41.81 |

| 24 | 1.65 | 443 | 49.8 |

** Not included in A.S.T.M. A 1023/A 1023M

Read Important Warnings and Information

Actual operating load may vary, but should never exceed recommended design factor or 20% of catalog breaking strength.

Drill Line – Typically used as a drilling cable in the oil, gas, and water drilling industries.

* EIPS (Extra Improved Plowed Steel) wire rope has roughly 10% more strength than regular IPS. Independent wire rope core ( IWRC ) provides added strength, reduces the amount of stretch. IWRC wire rope also is resistance to heat and provides extra corrosion resistance over a typical bright wire finish.

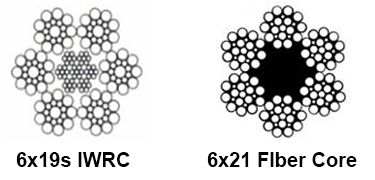

6 x 21 Poly Core Left Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 5/8″ | 0.66 | 16.7 |

| 3/4″ | 0.95 | 23.8 |

| 7/8″ | 1.29 | 32.2 |

| 1″ | 1.68 | 41.8 |

6 x 21 Poly Core Right Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 7/8″ | 1.29 | 32.2 |

6 x 21 IWRC Left Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 5/8″ | 0.72 | 20.6 |

6 x 26 IWRC Right or Left Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 3/4″ | 1.04 | 29.4 |

| 7/8″ | 1.42 | 39.8 |

| 1″ | 1.85 | 51.7 |

3 x 31 IWRC Left Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 3/4″ | 1.04 | 29.4 |

3 x 31 IWRC Right Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 3/4″ | 1.04 | 29.4 |

6 x 31 Poly Core Left Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 3/4″ | 0.95 | 23.8 |

6 x 31 IWRC Left Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 7/8″ | 1.42 | 39.8 |

6 x 31 IWRC Right Lay

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 7/8″ | 1.42 | 39.8 |

6 x 19S IWRC

| Diameter Inches | Approx. Wt. per Ft. in Lbs. | Breaking Strength in Tons* |

|---|---|---|

| 1.1/8″ | 2.34 | 65 |

| 1.1/4″ | 2.89 | 79.9 |

| 1.3/8″ | 3.5 | 96 |

Non Rotating 35×7 – Made according to Federal Specification RR-W-410E. Meets the performance requirements of API-9A, and A.S.T.M. A1023/1023M Wire Rope for general purposes, as applicable. Preformed, right regular lay.

| Part Number | Diameter In. | Tensile | Minimum Breaking Load (Tons) | Weight per Foot (Lbs) |

|---|---|---|---|---|

| 787600 | 5/16″ | 2160 | 7.26 | 0.208 |

| 789100 | 7/16″ | 2160 | 13.72 | 0.398 |

| 790100 | 1/2″ | 2160 | 18.45 | 0.521 |

| 791100 | 5/8″ | 1960 | 25.3 | 0.789 |

| 792550 | 3/4″ | 1960 | 35.68 | 1.134 |

| 794600 | 7/8″ | 1960 | 47.83 | 1.523 |

| 797000 | 1″ | 1960 | 62.8 | 2.05 |

| 799600 | 1-1/8″ | 1960 | 79 | 2.6 |

| 799150 | 1-1/4″ | 1960 | 98 | 3.22 |

| 800100 | 1-3/8″ | 1960 | 117 | 3.9 |

| 801000 | 1-1/2″ | 1960 | 138 | 4.62 |

| Part Number | Diameter mm | Tensile | Minimum Breaking Load (Tons) | Weight per Foot (Lbs) |

|---|---|---|---|---|

| 787550 | 7 | 2160 | 5.1 | 0.163 |

| 787600 | 8 | 2160 | 7.26 | 0.208 |

| 787625 | 8.5 | 2160 | 8.2 | 0.236 |

| 787650 | 9 | 2160 | 9.2 | 0.265 |

| 788500 | 10 | 2160 | 11.32 | 0.337 |

| 789100 | 11 | 2160 | 13.72 | 0.398 |

| 790000 | 12 | 2160 | 16.61 | 0.478 |

| 790100 | 12.5 | 2160 | 18.45 | 0.521 |

| 791000 | 14 | 1960 | 19.28 | 0.614 |

| 791100 | 15.87/16 | 1960 | 25.3 | 0.789 |

| 792150 | 18 | 1960 | 32.03 | 1.001 |

| 792550 | 19 | 1960 | 35.68 | 1.134 |

| 793000 | 20 | 1960 | 39.49 | 1.255 |

| 794600 | 22 | 1960 | 47.83 | 1.523 |

| 796500 | 24 | 1960 | 56.8 | 1.78 |

| 797000 | 25.4 | 1960 | 62.8 | 2.05 |

| 798400 | 26 | 1960 | 66.5 | 2.12 |

| 799100 | 28 | 1960 | 77.2 | 2.74 |

| 799250 | 32 | 1960 | 100.8 | 3.26 |

| 800500 | 36 | 1960 | 127.9 | 4.07 |