Jan 17, 2018

Pipe Size Dimensions (in) Approx. Weight (lb) MJ

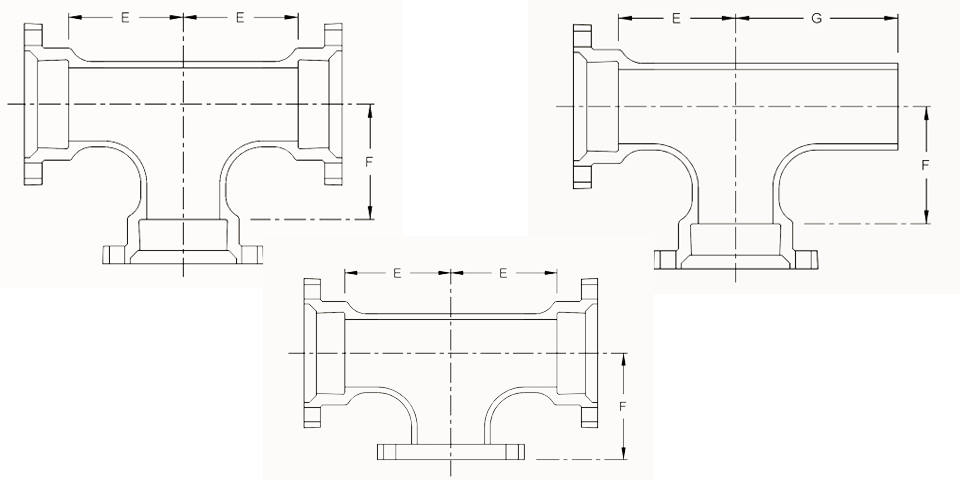

RUN (E)

Branch (F)

RUN (G)

* 2x2x2

3.25

3.25

–

21

* 3x3x2

3.25

3.25

–

45

3x3x3

5.5

5.5

13.5

58

* 4x4x2

4.8

4.8

14.5

68

4x4x3

6.5

6.5

14.5

77

4x4x4

6.5

6.5

14.5

78

4x4x6

8

8

–

112

* 6x6x2

8

8

–

78

6x6x3

8

8

16

112

6x6x4

8

8

16

110

6x6x6

8

8

16

119

6x6x8

9

9

–

158

8x8x3

9

9

17

155

8x8x4

9

9

17

157

8x8x6

9

9

17

175

8x8x8

9

9

17

199

10x10x4

11

11

19

–

10x10x6

11

11

19

258

10x10x8

11

11

19

268

10x10x10

11

11

19

300

12x12x4

12

12

20

318

12x12x6

12

12

20

325

12x12x8

12

12

20

335

12x12x10

12

12

20

392

12x12x12

12

12

20

396

14x14x12

14

14

22

540

14x14x14

14

14

22

585

* 16x16x4

15

15

23

600

16x16x6

15

15

23

615

16x16x8

15

15

23

625

16x16x10

15

15

23

645

16x16x12

15

15

23

660

16x16x16

15

15

23

740

18x18x6

13

15.5

–

710

18x18x8

13

15.5

–

674

18x18x12

13

15.5

–

749

18x18x18

16.5

16.5

–

945

20x20x6

14

17

–

849

20x20x8

14

17

–

892

20x20x12

14

17

–

896

20x20x16

18

18

–

1095

20x20x20

18

18

–

1258

24x24x6

15

19

–

1233

24x24x8

15

19

–

1234

24x24x12

15

19

–

1256

24x24x14

15

19

–

1220

24x24x16

15

19

–

1245

24x24x18

22

22

–

1735

24x24x20

22

22

–

1720

24x24x24

22

22

–

1947

30x30x6

18

23

–

2050

30x30x8

18

23

–

2060

30x30x10

18

23

–

2075

30x30x12

18

23

–

2090

30x30x16

18

23

–

2145

30x30x18

18

23

–

2170

30x30x20

18

23

–

2205

30x30x24

25

25

–

2880

30x30x30

25

25

–

2275

36x36x6

20

26

–

2439

36x36x8

20

26

–

2444

36x36x10

20

26

–

2535

36x36x12

20

26

–

2541

36x36x14

20

26

–

2570

36x36x16

20

26

–

2585

36x36x18

20

26

–

2610

36x36x20

20

26

–

2635

36x36x24

20

26

–

2792

36x36x30

28

28

–

3545

36x36x36

28

28

–

3450

42x42x24

23

30

–

3690

42x42x30

31

31

–

4650

42x42x36

31

31

–

4880

42x42x42

31

31

–

6320

48x48x24

26

34

–

4995

48x48x30

26

34

–

5140

48x48x36

34

34

–

6280

48x48x42

34

34

–

8130

48x48x48

34

34

–

8420

* These fittings are not included in AWWA C110/A21.10 For flange dimensions see Flange – ANSI Class 125, C110, DI

AWWA C110/A21.10 – Ductile-Iron and Gray-Iron Fittings (3″ to 48″)

ASME B16.1 – Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250 (Flange surfaces shall be faced and drilled in accordance with ANSI Class 125)

AWWA C104/A21.4 – Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

AWWA C111/A21.11 – Rubber-Gasket Joints for Ductile-Iron Pressure Pipe and Fittings

Ductile iron mechanical joint fittings 3″ through 24″ shall be rated for 350 PSI working pressure.

Flanged ductile iron fittings in 24 inch and smaller sizes may be rated for 350 psi with the use of special gaskets.

MJ – mechanical joint

PE – plain end

FLG – flange

error: Copy is disabled